Quality six times over

- 6 pre-compression rollers for a top quality chop

- Hydraulic drive shaft:

LOC steplessly adjustable from cab

Adjusts automatically with AutoScan

- Maximum protection against foreign objects:

Long path from metal detector to cutterhead

Metal detection across entire chamber width

Constant, safe and convenient Six pre-compression rollers and an 820 mm gap between the leading roller with metal detector and the rearmost roller not only enhance pre-compression but also protect the knives better against metal objects at high-speed intake. The hydraulic drive shaft automatically adjusts the LOC in line with the maturity of the crop, which is detected by the KRONE AutoScan sensor. If the engine speed drops below 1200 rpm as the load increases, the header and intake system are stopped automatically while the cutterhead continues to turn – because blockages caused by too low speeds cost time and money.

The universal cutterhead

- For grass, pre-wilted material, whole crop silage and maize

- Cutterheads with 20, 28 or 36 knives

- Plenty of carrying space under the knife carriers: high throughput and smoother running even on uneven swaths

- Knives quick and easy to insert and remove

OptiMaize XL – 20-knife drum: This drum cuts the kind of long lengths that are called for in some countries. LOC range: 20 blades 5 - 29 mm

OptiMaize L, M – 28-knife drum: This 28-blade unit is the universal drum. Used with just half the number of blades, it is perfect for producing long chops. LOC range: 28 blades 4 - 22 mm; 14 blades 8 - 42 mm

OptiMaize M, S – 36-knife drum: Handling massive throughputs and providing a wide range of cutting lengths, this 36-blade drum will earn its keep in no time. Remove half the blades and the unit is perfect for long chop applications. LOC range: 36 blades 3 - 17 mm; 18 blades 6 - 34 mm

More space for more crop: The knife carriers are arranged and designed to allow plenty of space under the knives. This extra carrying space means higher throughputs and smoother running, particularly in grass.

- 40 blades arranged in chevron formation

- High frequency of cuts

- High efficiency

- OptiMaize S

- High gas yields

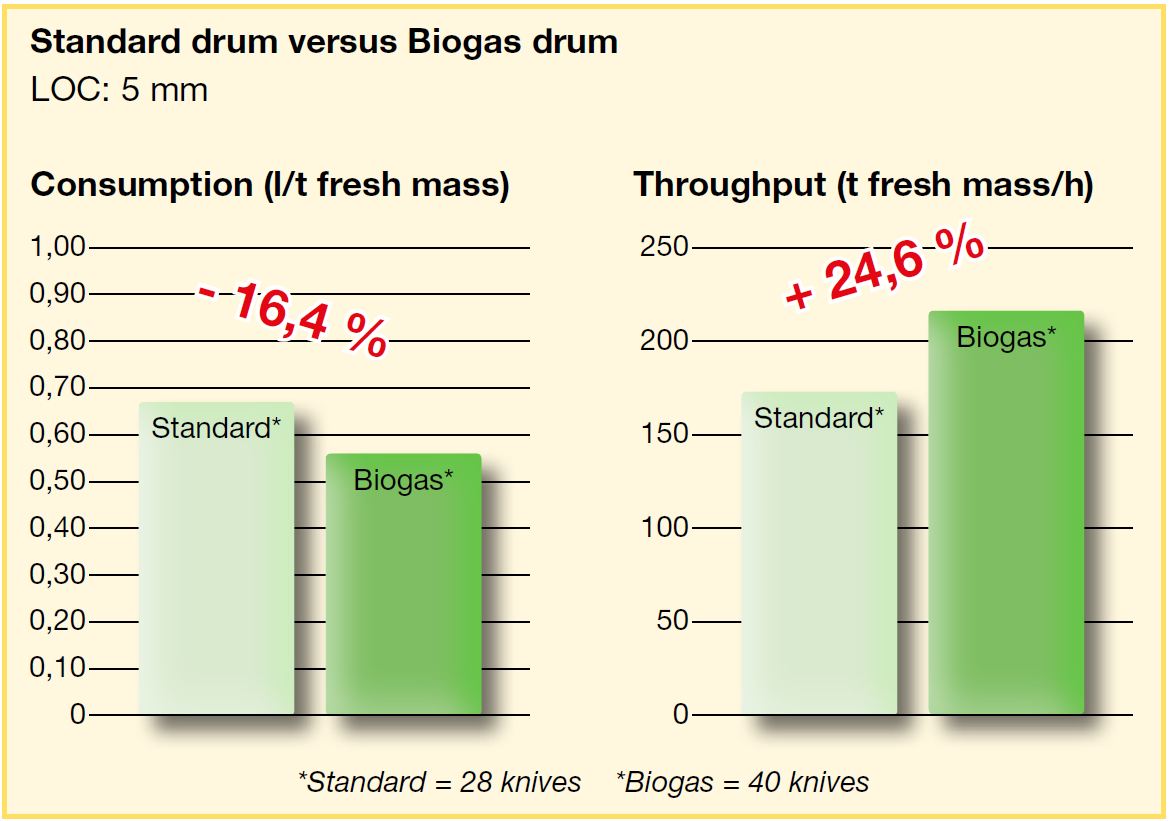

Higher output, lower costs: Working with a short LOC, the KRONE 40-knife Biogas drum can increase throughput by almost 25% compared with the 28-knife universal drum. What’s more, fuel consumption drops by up to 16% per tonne of chopped crop.*

The system for your success

- Perfect kernel treatment

- Huge 250 mm diameter roller

- Roll gap adjusted conveniently from the cab

- Perfect treatment: the right teeth for your corn

Our 250 mm (10") diameter rollers have a larger friction surface area than the smaller toothed rollers and can be operated at larger roll gap for greater effi ciency and fuel economy and better long stalk conditioning. The standard rollers revolve at a speed difference of 20 %. This can be increased to 30 % or 40 % for those who seek a higher conditioning intensity. These speeds are recommended for long chops where they ensure thorough conditioning and fracturing of long chops.

The roll gap is adjusted steplessly from the cab to the current conditions. The operator can view the current setting on the display.

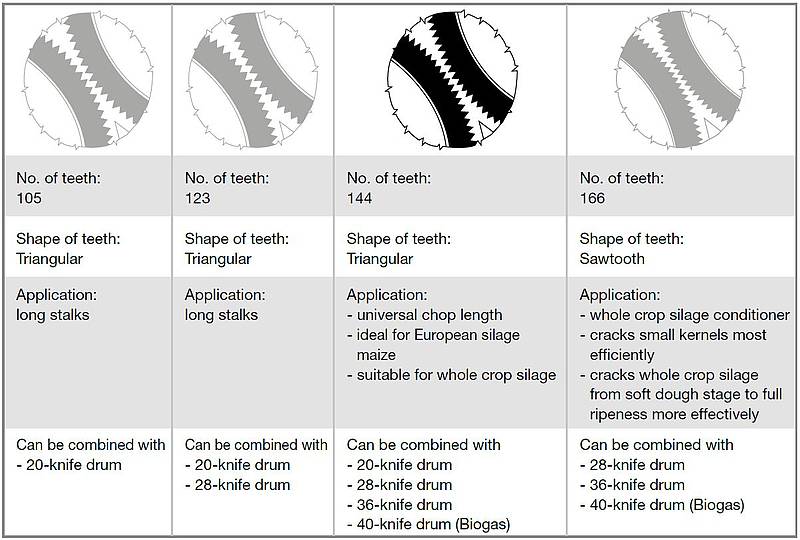

The rollers on the standard roller conditioner have 105, 123 or 144 teeth of a special triangular form for optimum conditioning.

The chrome coated roller conditioners are bespoke developments to deal with extreme conditions and offer a long service life. The friction surface is made up of saw teeth for maximum conditioning. Choose between 105, 123 or 144 teeth.

- Perfect conditioning and fracturing that preserves structure

- Large 265 mm (10.4") disc diameter for high output

- 2.5 times larger friction surface area than the roller conditioner

- Convenient disc gap adjustment from the cab

The gap between the discs can be adjusted to individual requirements to achieve perfect treatment at all chopping lengths – from OptiMaize S to XL.

With the discs on the outer rotor measuring 265 mm (10.4") in diameter and those on the inner rotor 135 mm, the discs are rotating towards each other at identical speeds but at different circumference speeds. This results in an enormous frictional effect that not only grinds all kernels but also fractures all stalks – even long chops – in an optimum way.

The disc conditioner has its teeth arranged so they form V-shaped gaps which increase the friction surface 2.5 times over the friction area on a roller conditioner. This makes for an enormous throughput and optimum conditioning.

Grass chute or corn conditioner

- Switch quickly from grass chute to corn conditioner and back

- Easy change thanks to drawer system

- No complicated changeover: done in just a few minutes

- Corn conditioner is quick and easy to remove

Installing and removing the corn conditioner The corn conditioner is quick and easy to install and remove. Once you have disconnected the grass chute, you simply tilt the corn conditioner downwards over the gliding plane. Two hydraulic drums make for easy handling and very fast set-up times.

Drawer format for a quick change: With VariQuick, BiG X can be switched from maize to grass mode and back again in no time. The sliding rail enables the grass chute and the corn conditioner to be moved together as one unit with a hand pump and positioned at the appropriate point in the crop flow. For longer use in grass, the corn conditioner can be folded down and removed completely to the side.

A KRONE exclusive

- Consistent performance with irregular crop flow

- Extremely smooth running even on uneven swaths

- High throughput

- Top quality chop

- Extremely user-friendly

Outstanding quality chop even in an uneven crop flow: The spring-loaded cutterhead floor is connected to the anvil of the counterblade at the front. This means that the clearance between the cutterhead floor and the knives is always constant. So any movement of the spring-loaded cutterhead floor to compensate for an uneven crop flow won’t affect the quality of chop.

Consistent throw with a tight crop stream: The spring-loaded backplate of the crop accelerator ensures maximum crop output in all conditions, filling the trailer to perfection.

Adjustable crop throw

- Optionally adjustable crop throw

- Tight crop stream even with a long crop throw

- The shorter the crop throw, the less power is needed

- Fill trailer accurately with no spillage

Short crop throw: For a short crop throw with the trailer driving alongside, the crop stream leaves the spout at a lower speed. This saves power, which can be used to boost chopping output.

Long crop throw: With the trailer following behind, the crop stream needs to be ejected from the spout at a higher speed. A strong, tight stream is needed to cover the long distance over the tractor to the rear wall of the trailer.

Neat filling – efficient and effective

To avoid spillage while filling the trailer, the crop stream must be tight and the crop throw must be set to the exact distance. The operator can adjust the crop throw from the cab quickly and easily by adjusting a hinged flap in the backplate of the crop accelerator. As the accelerator needs less power with a short crop throw, the freed-up engine output can be used for chopping, thus increasing throughput.

Crop accelerator: The paddles are designed for high crop output and guide the crop flow towards the middle.

Adjusting the crop throw distance: The crop throw is controlled via the hinged flap on the backplate of the accelerator. For a short throw, the flap is tilted out of the crop flow, so there is little contact between the crop and the accelerator. For a long throw, the flap is tilted into the crop flow, so there is more contact between the crop and the accelerator.

Joystick control: The crop throw is quick and easy to control with the buttons on the joystick control panel.

Armrest buttons: Additional control buttons are provided in the armrest for extra convenience.

Stepless electric motor control: The hinged flap on the backplate of the accelerator is adjusted steplessly via an electric servomotor.

Powerful and fuel-efficient

- 6-cylinder in-line MTU engines

- Tier 4 final / Stage IV emission standard

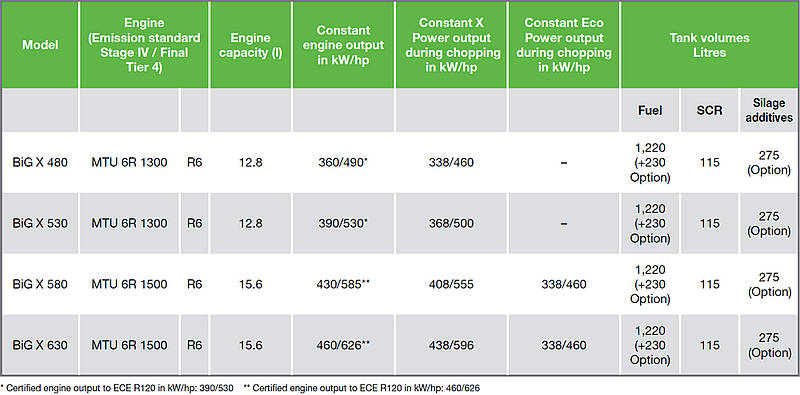

- Maximum constant engine outputs from 490 to 626 hp

- Extremely economical, smooth running

BiG X 580 and 630 PowerSplit: PowerSplit adapts the engine output automatically to the harvest conditions. EcoPower is used in situations in which less engine power is needed. XPower delivers maximum output for tough conditions. This technology gives you more flexibility and saves fuel.

In-line engines mounted sideways: The engine is located right at the back of the machine and is mounted sideways for optimum weight distribution. The direct driveline to the crop flow components translates into great fuel economy. Common Rail injection technology makes these MTU in-line engines highly fuel-efficient.

Strong and reliable

- Simple design

- Direct power transmission with extra strong poly V-belts

- Long service life

- Separate drive shafts on intake system and headers Reverses when cutterhead idle

- Separate reliable hydrostatic pump drive

Clever design: The header and intake system are driven via oil pumps flange-mounted onto a gearbox driven by the engine via an extra strong poly V-belt. This concept allows the header and intake speeds to be adjusted steplessly.

Ground drive: The hydrostat pump is powered via a 5-groove poly V-belt driven separately by the engine which starts up automatically when the engine starts. The direct driveline works reliably, guaranteeing maximum safety.

Direct driveline – full throttle: The transversely mounted engine allows the hydro pump, the cutterhead, the crop accelerator and the header and intake pumps to take engine power efficiently off poly V-belts, eliminating the need for a power take-off gearbox. All crop flow components are activated via a belt clutch.

Innovative drive train

- Front wheel drive as standard, four-wheel drive optional

- Strong Bosch Rexroth wheel motors

- Traction control with three travel modes

- Stepless speed range from 0 to 40 km/h

Front-wheel drive – four-wheel drive: BiG X 480, BiG X 530, BiG X 580 and BiG X 630 are available with optional hydraulic four-wheel drive via wheel motors. Machines with front-wheel drive have hubs on the rear wheels instead of wheel motors. Both drive trains are designed for speeds of up to 40 km/h.

Planetary gears: The wheels are powered by Bosch-Rexroth planetary gearboxes. This type of gearbox has the advantage that it spreads the load across several planetary wheels, delivering high torques in a compact unit.

A KRONE exclusive: The front wheels feature eccentric, height-adjustable wheel motors to maintain the position of the pick-up, intake system and cutterhead floor for the next pass, regardless of the size of the wheels. So an optimum, constant crop flow is ensured at all times.

Completely manoeuvrable: This drive concept with wheel motors has an extremely small steering angle of just 50° – perfect for tight turns and matching up to the previous row on headlands with an 8-row maize header.

Tyres with a purpose: The BiG X 480, 530, 580 and 630 models can take tyres up to 900/60 R 42. Large tyres ensure maximum ground clearance, lowest soil compaction and an extremely comfortable ride.

Down to the very last detail

- Best night vision

Optional LED lighting kit

- Huge optional spare fuel tank: carry up to 1450 l diesel

- Easy access to service and maintenance points

Turn night into day: Sixteen headlights light up your work area perfectly, making night shifts less stressful and safer. An optional LED lighting kit enhances visibility even further.

Up to 1,450 l fuel on board: The huge, basic specification fuel tank holds up to 1,220 l diesel. And there’s also room for 115 l urea on board. So there’s no need to stop what you’re doing to refuel. An auxiliary 230 l diesel tank and a 275 l silage additive tank are available as an optional extra.

Everything within sight: The optional LED maintenance lights give a clear view of all drive assemblies and maintenance points in the dark. Optional LED lights are also available for the access ladder.

Plenty of room: There’s plenty of room between the cooling system and the crop flow on the BiG X 480, 530, 580 and 630 models, giving easy access to all components for cleaning and maintenance.

The ultimate level of comfort

- Spacious

- Maximum operator comfort

- Excellent all-round vision

Wider, quieter and brighter: The wide cab with its narrow posts is spacious and gives the operator the best possible view of wide headers. The double floor keeps noise in the cab to a minimum. Sixteen H9 lights provide perfect illumination, and LED lights are available as an option.

Everything within sight: High side windows and slim posts give the operator an unobstructed view of the spout even with filling heights as high as 6 m, making filling trailers safer and more efficient.

Ergonomic, convenient and easy to use: The ergonomic joystick with user-friendly icons gives the operator fingertip control of multiple machine functions. Designed specifically for BiG X, the slim stick sits comfortably in the hand. With more than 20 programmed functions, it not only controls ground speed and direction of travel but also the header and spout.

Clutter-free: The controls for lights, heating and air conditioning are arranged on a panel above the front windscreen. The Follow-Home function lights your way as you get down from the cab. After you switch off for the night, some headlights stay switched on for several minutes, allowing you to find your way safely.

Little helpers: The control box records all the machine data and displays it on the high-definition colour screen. Various settings can be changed on it, such as stepless LOC adjustment. The clearly designed control unit next to the seat houses all controls that operate the various machine functions, including ground drive and cutterhead drive.

DigitalSystems is the electronic control system from KRONE that optimizes machine utilization and operator comfort. It gives peace of mind in tough conditions and displays all relevant harvest data.

AutoScan: The photo-optical sensor in the middle of the maize header measures the maturity of the plant and automatically adjusts the LOC. Green maize is cut to longer lengths for a better structure and to reduce silage effluent in the clamp. When harvesting dry maize, the material is cut to shorter lengths for more effective compaction in the clamp. AutoScan reduces operator effort and saves fuel, because the stalks are only cut as short as necessary and not as short as possible. AutoScan comes as standard with all KRONE machines and is not an expensive extra.

ConstantPower: ConstantPower automatically adjusts the machine‘s ground speed to the engine loading. Select the desired engine loading at the touch of a button and the machine will adapt its ground speed fully automatically to the crop and material being harvested. This standard feature reduces operator stress and ensures maximum throughputs with minimum fuel consumption. In combination with AutoScan, this system takes the overall quality of chop and machine performance to a whole new level.

ForageCam: As an optional extra, a CCTV camera on the spout remotely transmits footage to the forager’s in-cab terminal and to the terminal on the trailer. The CCTV camera helps the operator utilize the full load space in the trailer and reduces fatigue at the same time. The system can be expanded to communicate with multiple receivers on all the trailers in a large haulage chain.

RockProtect: The six pre-compression rollers are powerful and soft at the same time. The optional RockProtect system provides intelligent protection from damage by stones as it halts the pre-compression rollers fully automatically within milliseconds after the system detects a stone. The operator sets the sensitivity of systems. More protection – more peace of mind.

ISOBUS autoguidance: As an optional extra, BiG X can be supplied ready to accept various manufacturers’ ISOBUS guidance systems. On the move, the operator activates autoguidance using the KRONE joystick simply by pressing a button, then watches the system guiding BiG X down the track. Autoguidance reduces operator fatigue, boosts work rates in broadcast seeded crops and increases efficiency.

NIR crop moisture sensing system: The optional NIR sensor provides exact information on crop moisture levels. The information can be allocated to the area harvested in the customer memory. The NIR sensor is easy to install on the BiG X spout and is protected from damage by a cover.

CropControl: The optional KRONE CropControl yield metering system measures the volume of crop harvested quickly and accurately at the touch of a button. With CropControl you can seamlessly document yield information on all fields harvested.

AutoCalibrate: AutoCalibrate is the re-mote calibration tool for the BiG X‘s yield metering system. It operates via a weighing system installed on one of the trailers in the harvest chain. Both the trailer and the BiG X forager are equipped with data loggers that communicate via a mobile network. Calibration takes place while the ‘calibrating machine’ is being filled. AutoCalibrate is highly accurate and is the first system of its kind to eliminate the trip to the weighbridge.